By Dr. Sandeep Gavali, Dr. K.P. Kale, Dr. Sunil Nadgauda, Dr. Parag Mahadik and Dr. Sudhir Kale from Venky’s India Limited, Pune

As per current scenario, oil is one of the major source of energy in poultry feed for fulfillment of required energy levels.

According to Baião NC and Lara LJC (2005) the term fat (animal or vegetal) is used as a synonym for lipid in the human food as well as in the ingredients for animal nutrition. The addition of fat to diets, besides supplying energy, improves the absorption of fat-soluble vitamins, diminishes the pulverulence, increases the palatability of the rations, and increases the efficiency of the consumed energy (lower caloric increment). Furthermore, it reduces the passage rate of the digesta in the gastrointestinal tract, which allows a better absorption of all nutrients present in the diet.

Considering importance of fats and oils in poultry feed, we want to discuss following important points:

- Use of Fats and Oils in poultry diet

- Emulsifier and their usage in poultry feed

- Field trial reports of the emulsifier (Emulso-V)

Fats and Oils in poultry feed:

According to Murugesan G. R., historically, starch (specifically maize/corn starch) has been the primary energy source for poultry feed. As maize is now being increasingly utilized in ethanol production, the cost and availability of starch as a low-cost energy source is being adversely affected. This makes dietary energy the costliest component in poultry feed. Energy costs will continue to drive grain prices, as more grain is diverted towards bio-fuel production, impelled by high crude oil prices. While continual usage of maize increases dietary costs and reduces margins, reduction of dietary energy might result in either slowed growth rates and/or reduced feed efficiency. Another option, however, is to use supplemental fats and oils to increase dietary energy content. This would allow for continued performance and give the flexibility to poultry producers when pricing ingredients. Fats and oils have been used by the growing poultry industry around the globe as a supplemental dietary energy source in poultry feed to yield higher levels of metabolizable energy at an economically justifiable price. Hence, understanding fats and their metabolism is a critical factor when it comes to efficient utilization of the dietary energy contributed by fat/oil supplementation.

For understanding better usage of fats and oils and to increase its utilization, knowledge of the following points is essential:

- Selection of fats and oils

- Quality of Fats and Oils

- Broiler’s Diet

- Digestion and Absorption of fats and oils

1. Selection of fats and oils:

Introduction of fats and oils:-

The term “fat” is used as a synonym for lipid and refers to triglycerides or triacylglycerols of several profiles of fatty acids. Oils are esters of glycerol as with fats; however, oils are liquid unlike fats which are solid at room temperature (Lehninger et al., 2008).

Fats and oils both are composed of triglycerides (having three fatty acids with one glycerol backbone).

Fatty Acids –

- Short Chain Fatty Acids – Having 2 to 5 numbers of carbon atoms in their structure. For e.g. Propionic acid, Butyric acid.

- Medium Chain Fatty Acids – Having 6 to 12 numbers of carbon atoms in their structure. For e.g. Capric acid, Caprylic acid.

- Long Chain Fatty Acids – Having 13 to 21 numbers of carbon atoms in their structure. For e.g. Palmitic acid.

- Very Long Chain Fatty Acids – Having above 21 numbers of carbon atoms in their structure.

Saturated and Unsaturated Fatty Acids –

- Saturated Fatty Acids – Having no double bond in their carbonic chain structure, high melting point than unsaturated fatty acids, less polar and available in animals fats in large quantity.

- Unsaturated Fatty Acids – Having one or more numbers of double bonds in their carbonic chain structure, less melting point than saturated fatty acids, more polar, cis as well as trans type of fatty acids, available in vegetable oils in large quantity.

Triglycerides –

A)

- Simple Triglycerides – Having same types of fatty acids attached to their glycerol backbone.

- Mixed Triglycerides – Having different types of fatty acids attached to their glycerol backbone.

B)

- Triglycerides with Saturated Fatty Acids – Having all three saturated fatty acids in their structure.

- Triglycerides with Monounsaturated Fatty Acids – Having one double bond in their unsaturated fatty acids structure.

- Triglycerides with Polyunsaturated Fatty Acids – Having two or more number of double bonds in their unsaturated fatty acids structure.

Fats –

Fats are having more number of saturated fatty acids (no double bond in their carbonic chain structure), fats are less polar than oils and having high melting point, hence they are solid at room temperature. They are made up of simple or mixed types of triglycerides with more number of saturated fatty acids.

Oils –

Fats are having more number of unsaturated fatty acids (one or more numbers of double bond in their carbonic chain structure), high polar than fats and having less melting point than fats, hence they are liquid at room temperature. They are made up of simple or mixed types of triglycerides with more number of unsaturated fatty acids.

With considering above classification of Fatty Acids, Saturated and Unsaturated Fatty Acids, Triglycerides and Fats and Oils, selection of best fats and oils are as per below:

- Oils are preferred than fats as they are having more numbers of unsaturated fatty acids.

- The increase in the length of the carbonic chain of saturated fatty acids increases the melting point of the fat and the presence of the double bond decreases the melting point. The longer is the chain, the smaller is the number of double bonds, and less soluble it will be in water. The geometry of the double bond also influences the melting point.

- Trans fatty acids have higher melting point than their cis isomers.

- All types of unsaturated fatty acids are more preferable than all types of saturated fatty acids.

- Long chain unsaturated fatty acids can provide more metabolizable energy to the birds than all other fatty acids and also helps to form more micro micelle for better absorption of oils.

- Triglycerides with Polyunsaturated Fatty acids (Cis type of long chain unsaturated fatty acids) can provide more metabolizable energy to birds than Triglycerides with Monounsaturated Fatty acids and Saturated Fatty Acids.

- U/S ratio (Unsaturated/Saturated) of fats/oils inclusion in poultry diet should be at least 4:1 for better utilization and absorption of fats/oils.

Additionally, there are some points need to consider during selection of fats/oils for poultry diet inclusion rather than above mentioned criteria for better utilization and prolong life of fats/oils.

2. Quality of Fats and Oils –

The quality of fats/oils is most essential part of selection of oils/fats for poultry diet and to maintain the good quality of selected oil/fat is also important for it’s prolong life and it is depends on following points –

- Oxidative Rancidity – Polyunsaturated fatty acids are more prone to oxidative reactions or to form oxidative rancidity as they are having more number of double bonds. Hence for avoiding the same we need to use some antioxidants. e.g. natural antioxidants (vitamins A and E), the synthetic α-tocopherol and other phenolic antioxidants (BHA Butyl hydroxyanisole, BHT – Butyl hydroxytoluene, TBHQ tert-butyl-hydroxyquinone, PG 3,4,5-Trihydroxybenzoic acid propyl ester) and the non-phenolic antioxidants (Ethoxyquin Ethox, 6 ethoxy-1,2 dihydro-2,2,4 trimethyl quinoline) are effective in inhibiting oxidation. BHA and BHT are effective in stabilizing animal fats. TBHQ is effective in stabilizing both animal and vegetal fats. The mixture of TBHQ with BHT and/or BHA is widely used in the control of oil and fat oxidation. PG is the most adequate to stabilize animal fats (Butolo, 2001; Papas, 1993 cited by Gómez 2003).

- MIU (Moisture, Impurities and Unsaponifiable) – Max level should be 1%.

- Acidity (Free Fatty Acids) – It has been suggested that for each 1% of increase in acidity, 10 kcal of metabolizable energy is lost per kg of diet/ ingredient (Barbi & Lucio, 2003).

- Saponification value – It is always higher when triglyceride chains are shorter.

- Peroxide value – Max. 20 meq is accepted per kg of oil/fat (or depends on the nature of fatty acids available in oil/fat).

- Iodine value – It is considered better for stability of fats/oils. Iodine value between 70 and 120 or above (or depends on oil/fat).

3. Broiler’s Diet –

Total requirement of energy is high in broiler birds. For fulfillment of their energy requirement oil/fat is the best source than other carbohydrate and protein rich sources as heat increment during fatty acids conversion from oil/fat is lesser than carbohydrate and protein.

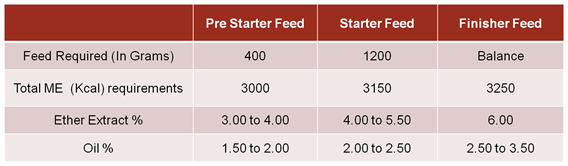

Generally following broiler diet specifications are followed in the poultry industry for better broiler performance.

Table 1. Broiler’s Diet

As per physiology of birds they are having capacity to utilize or digest limited quantity of oils/fats when we are offering energy in the form of oils/fats. Endogenous emulsifiers are not much efficient in the digestion of fat (Dr. Rajesh Singh, 2019).

4. Digestion and Absorption of fats and oils

Fat digestion

The digestion and absorption of fat in the chicken occurs mainly in the small intestine (Scott et al., 1982). The presence of digesta, with intact dietary fat in the duodenum, stimulates cholecystokinin secretion, which in turn induces the secretion of pancreatic enzymes and bile (Friedman and Nylund, 1980). While bile salts emulsify fat along with co-lipase providing more surface area for the enzymes to act upon, lipase hydrolyses the emulsified triglycerides on sn-1 and sn-3 positions to release Monoglycerides and free fatty acids (Mu and Hoy, 2004). Cholesterol esterase hydrolyses cholesterol-fatty acid esters into cholesterol and free fatty acids (Mu and Hoy, 2004). Also large amounts of endogenous phospholipids enter through bile, predominantly Phosphatidylcholine in addition to dietary phospholipids. Phospholipase A2 cleaves phospholipids at the sn-2 position to release lysolecithins and free fatty acids (Scott et al., 1982).

Fat absorption

Bile salts are biological surfactants as well as detergents, which are amphipathic i.e., they have both hydrophobic and hydrophilic ends (Mu and Hoy, 2004). When the concentration of bile salts in the lumen is at or above “critical micellar concentration,” they arrange themselves on the surface of lipid digestion products, with their hydrophobic ends turned inward and hydrophilic ends turned outward (Free Fatty Acids, Monoglycerides, Cholesterol and Lysolecithin), forming “Mixed Micelles” (Garrett and Young, 1975). Long-chain unsaturated fatty acids have greater ability to form micelles, they may act synergistically in the absorption of saturated fatty acids when mixed with them (Ferreira, 1999). To get their lipid content absorbed actively by enterocytes, these mixed micelles can pass across the unstirred water layer, which bathes the enterocytes (Iqbal and Hussain, 2009). Inside the enterocytes, the MG, free fatty acids are re-esterified to form triglycerides and together with cholesterol, lipoproteins and lysolecithins, are assembled into portomicrons (Stevens, 2004). Around 15% of fatty acids present in the lumen are catabolized in the mucosal epithelium towards the maintenance energy requirement (Noy and Sklan, 1996). Short chain fatty acids and free glycerol are absorbed directly through passive uptake (Gropper et al., 2008). The portomicrons, short chain fatty acids and free glycerol are transported through the portal venous system to the liver, since unlike mammals the lymphatic system of the birds is not well developed (Bensadoun and Rothfeld, 1972).

Role of Lipoproteins:

Very low density lipoproteins (VLDL) – carry triglycerides from the liver to the extra hepatic tissues like the ovary (for egg yolk synthesis) or muscle (for energy) (Phan and Tso, 2001).

High-density lipoprotein cholesterol (HDL-C) – “Good cholesterol” because HDL-C takes up excess cholesterol and carries it to the liver for removal.

Low-density lipoprotein cholesterol (LDL-C) – “Bad cholesterol” because it deposits excess cholesterol in walls of blood vessels.

Difficulties in first few days of life:

Secretion of bile acids/salts and pancreatic lipase enzyme are less in first 14 to 21 days of life. Hence, external supplementation of emulsifier is essential for better digestion and absorption of fats / oils.

According to Carew et al. (1972) the capability to absorb corn oil increased from 84% to 95% from the first to the second week of age and absorption of tallow has increased from 40% to 79%.

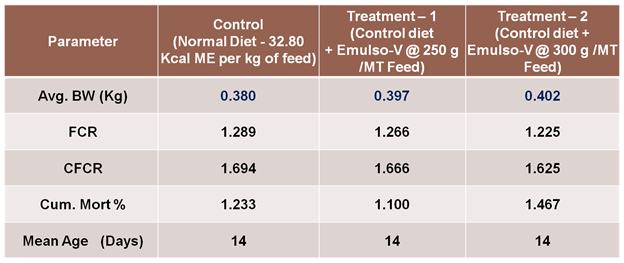

We have done one trial on broiler’s based on above hypothesis using Emulso-V (PEGR based emulsifier from Venky’s) and following are our findings:

Table 2. Trial of Emulso-V on broiler birds

* Note – Energy level is reduced by reducing 6 kg soya oil per ton of feed.

Addition of emulsifier showed better weight gain as compared to control diet. Exogenous or external supplementation of emulsifiers is most important in broilers for better digestion and absorption of fats/oils during early life.

Emulsifier:

Emulsifier – A substance that stabilizes an emulsion and having water loving head (Hydrophilic) and an oil loving tail (Hydrophobic).

Emulsion – It is a mixture of two or more immiscible liquids. They are having two types oil in water emulsion and water in oil emulsion.

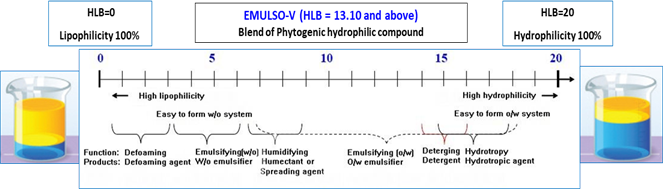

HLB Value (Hydrophilic-Lipophilic Balance) – HLB is the tool or scale which is used for the evaluation of the type of emulsifiers. HLB value ranges between “0 to 20” for different emulsifiers.

HLB – 4 to 6 are using as water in oil emulsifiers, HLB – 7 to 9 are using as wetting agents, HLB – 8 to 18 are using as oil in water emulsifiers, HLB – 13 to 15 are using as Detergents and HLB – 10 to 18 are using as Solubilizers.

Bile salts are acting as natural emulsifier which is having HLB (Hydrophilic-Lipophilic Balance) value around 18. i. e. more hydrophilic, also there are various commercial emulsifiers available in the market.

Birds are consuming 2.5 to 3 times more water than the feed consumption, and total fat in feed is around 6 % or slightly more (depends on the feed ingredients), hence water consumption is approx. 30 – 40 times more than total fat intake, Hence birds require emulsifier which dissolve oil in water and should have more Hydrophilicity or HLB value (min. 8 and max. 18).

Fig. 1. HLB Scale

Commercial emulsifiers –

- Lecithin (Phospholipids) – More lipophilic emulsifier with low HLB value hence not suitable for poultry. Its structure is having two lipophilic tails and one hydrophilic head.

- Lysolecithin (Lysophospholipid) – Hydrophilic emulsifier with O/W emulsifier property but HLB is below 13. It is derived from lecithin and having one lipophilic tail and one hydrophilic head.

- GPEGR (Glyceryl Polyethylene Glycol Ricinoleate) /PEGR (Polyethylene Glycol Ricinoleate) / Emulso – V (Venky’s) – Hydrophilic emulsifier with O/W emulsifier property and HLB value is around 13.10 and above. It is derived from castor oil and its structure is having more hydrophilic portion. Castor oil is rich in long chain unsaturated fatty acids which acts as a potent emulsifier itself. Toxicity of enzyme ricin is removed after heat treatment.

About GPEGR/PEGR (Emulso – V) –

Properties –

Properties and Uses –

- PEGR is non toxic and naturally biodegrades and is recognized as Generally Recognized as Safe (GRAS).

- PEGR is non-ionic and stable in broad range of pH and high temperatures and is suitable for pelleted feeds.

- “Nutritional Emulsifier” as it consumes little energy than other emulsifiers like soy lecithin and dissolved in gut by mechanical stirring.

- It can increase digestibility of long chain saturated fatty acids (C16 and C18) hence; it is economical as animal fats and some vegetable fats (Like Palm oil) contains LCFA (Max. saturated).

- It reduces liver fat / abdominal fat pad and circulatory lipids as well as dietary lipids are utilized in better way.

- PEGR utilize more fat and can be used in least cost feed formulation for energy equivalence.

- PEGR act as a bio surfactant.

- PEGR is compatible with NSPs because PEGR reduces viscosity (NSPs having property to increase the viscosity in GIT and increased viscosity leads to inadequate absorption of nutrients and impaired peristaltic progress of chyme through intestine which may leads bacterial overgrowth and micro flora reduces binding of bile salts to fat in upper intestinal tract, hence wash out the fats with reduces its utilization).

- PEGR is a good emulsifier and can produce effects inside as well as outside the body.

- Inhibition of fungal growth – It bounds moisture (as moisture is inside the feed particle) it does not evaporate thereby maintains the nutrient value intact without any loss and inhibits the growth of yeast and mold. It also helpful for uniform mixing of not only fats or oils but also liquid amino acids, liquid vitamins and liquid acidifiers.

- PEGR acts as a lubricant during feed production which helps in better pellets production with less energy consumption. Also, due to the lubrication property, there is less friction in the dye which helps to increase the dye life.

- The process of pelletizing feed requires the use of steam at conditioning however steam and oil have no compatibility. The PEGR are known to improve the feed production process by reducing the interfacial tension between two immiscible phases of oil and water leading to quality feed production.

- PEGR having excellent property to work synergistically with bile salts.

- Aqueous solution of PEGR is stable in the presence of low concentrations of electrolytes such as acids or salts.

Mechanism of Action –

- Upon entering into the Jejunal area or small intestine, Emulso-V starts breaking the large fat globules into smaller one and helps to expose their surface active area.

- Pancreatic lipase identify exposed active surface of fat globules and starts its hydrolysis mechanism (i.e. Triglycerides from oils or fats divides in to one Monoglyceride and two Fatty Acids)

- Emulso-V helps to form more “Micro micelles” with the help of Monoglycerides, Phospholipids and bile salts. “Micro micelles” can be absorbed easily through intestinal villi.

Trial Reports:

We have conducted several trials in broilers using Emulso-V as an emulsifier to study the efficacy of emulsifiers.

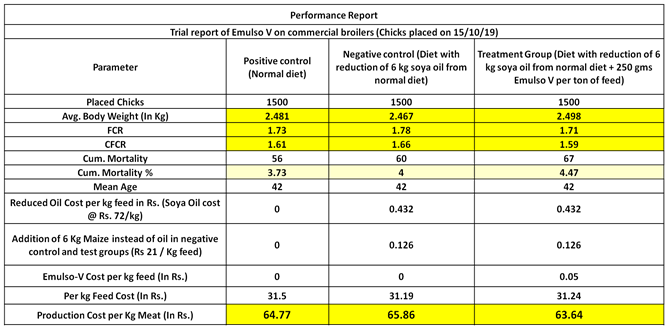

Note – In below mentioned trial, we have reduced 6 kg soya oil from per ton of feed and same is replaced with 6 kg maize per ton of feed resulting in reduction of 32.8 kcal ME per kg of feed in negative control as well as treatment groups.

Table 3. Performance Report:

The trial shown that usage of Emulso-V improved broiler performance resulting in reduction of production cost/kg broiler weight as compared to control groups (Positive and Negative control), by better utilization of added fats/oils in the feed.

Table 4. Fat digestibility trial:

Conclusion – Emulso – V helps to increase total digestibility of fat.

*PC – Positive Control (Normal Diet), *NC – Negative Control (diet with reduction of 6 kg soya oil from normal diet and addition of 6 kg maize per MT of feed).

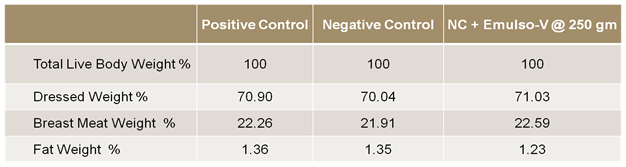

Table 5. Fat yield trial:

Conclusion – Emulso –V helps to reduce abdominal fat pad, liver fat and helps to increase breast meat weight as well as dressed weight.

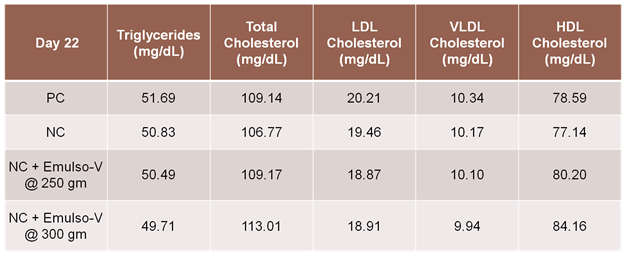

Table 6. Serum cholesterol level:

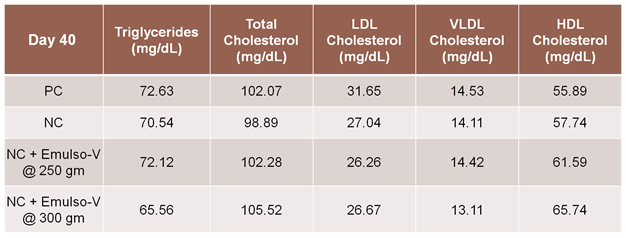

Table 7. Serum cholesterol level:

Conclusion – Emulso – V / PEGR is responsible for the increase a total serum cholesterol level but it increases HDL not LDL and Triglycerides and same is explained by Verlag Eugen Ulmer (2019).

Recommended dosage levels:

Dose of Emulso – V is 250 to 300 g per ton of feed (we can reduce 32.8 kcal energy per kg of feed by using Emulso – V).

Summary (about Emulso-V):

- Emulso-V (A unique nutritional synthetic emulsifier) is a blend of Phytogenic Hydrophilic Emulsifiers and major constituent is Glyceryl Polyethylene Glycol Ricinoleate which having strong activity to dissolve oil in water.

- It has good HLB value (Above 13.10) with strong surfactant activity than Phospholipid (Lecithin), Lysophospholipid (Lysolecithin) and other commercial emulsifiers and synergistically acts with Bile salts.

- In Vivo Activity – It has good activity to increase surface active area of fat/oil which triggers the activity of pancreatic lipase in fat digestion process and helps to form more micro-micelle for better absorption of fat and fat soluble vitamins. It reduces viscosity also, hence compatible with NSPs.

- In Vitro Activity – Binds moisture (i.e. moisture available at inside of grinded particles) for avoiding its evaporation, good lubricant property beneficial for pellet mill and reduces interfacial tension between steam and feed during conditioning process.

- It helps to reduce abdominal fat pad, liver fat and helps to increase fat digestibility and HDL cholesterol (good cholesterol).

- It helps to gain average body weight with reduction in FCR.

- Energy saving effects (we can reduce upto 32.80 Kcal ME per kg of feed with using Emulso-V as per recommended dosage) which can help reduces cost of feed formulation.

- Strongly compatible with all kinds of oils (either rich in saturated or unsaturated fatty acids, e.g. Tallow, RB oil, Palm oil, Blended oil and Soya oil etc), grains having NSPs and some amount of saturated fatty acids (e. g. Wheat, SBM, Broken Rice etc).

- Dose – 250 to 300 gms per MT of feed.

References –

References will be shared on demand.