Purchase of a sealed silo is an important investment for better grain insect control. Insects must be controlled in stored grain as they damage grains and excrete moisture that can migrate to the headspace and cause moulding. This damage and mould downgrade the entire content of the silo when it mixes during outloading. Grain insects can also consume large amounts of grain and taint it with their excretions. Regulations prohibit the sale and handling of infested grain.

Fumigation chamber

A sealed silo will not control insects on its own. It is a fumigation chamber, designed to retain a lethal concentration of gas for a specified time. This will ensure 100% control of insects at all stages of their life cycle and minimise the development of phosphine resistance.

Sealed silos save time at fumigation. Simply place tablets on top of the grain in trays. There is no need to probe them in. The gas will circulate on air currents moving through the silo and control insects without having to move the grain.

Time and concentration needed

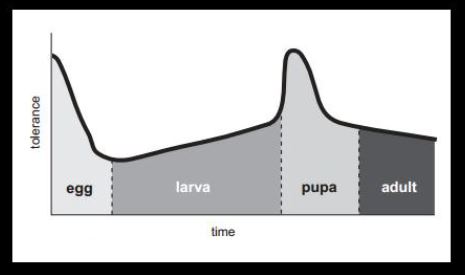

Grain insects pass through four stages in their life cycle from egg to larva to pupa to adult. The most phosphine-tolerant stages are the egg and pupa (Figure 1).

The concentration of phosphine needed to control all stages of the insects is 100ppm throughout the silo. Control will not be achieved unless this concentration is maintained for at least seven days. A seven to ten day fumigation period is recommended to allow time for the tablets to fully liberate their gas followed by a ventilation period of an additional three days.

Fumigation will fail if the silo leaks. When wind blows against a leaky silo, the chimney effect caused by the pressure difference draws the gas out of the silo. With poor fumigation adult insects may be killed, giving the illusion of a successful fumigation. But some eggs and pupae will survive because they are more tolerant to phosphine and in a short time you will find adult insects once again infesting the grain.

Grain temperature must also be taken into account. Above 25ºC an exposure period of seven days is enough. However, when temperatures are between 15 and 25ºC, a period of 10 days is needed. Do not fumigate when grain temperatures are below 15ºC, or when grain moisture content is below 9%.

Recommended dose rates

An Standard Pressure Test AS 2628 (2010) requires a halving pressure for a new silo of 5 minutes from 25mm head of water gauge. Research done on-farm suggests that a three-minute halving pressure for existing silos is an adequate standard to conduct an effective fumigation. In a silo sealed to Australian Standards, a dose rate of two tablets per tonne of silo capacity is recommended. For example, a 50 tonne silo will always need a dose of 100 tablets. If the silo is partly full and holds 20 tonnes of grain, the phosphine dose would be the same. A 50 tonne silo needs 100 tablets every time.

Fumigating unsealed silos

Effective fumigation is impossible to achieve in an unsealed silo (or any unconfined airspace). Do not fumigate in a silo that is not well sealed. Fumigating in an unsealed silo or field bin is an off label use, and doing so leads to an ineffective fumigation and the development of a strongly phosphine resistant population. In unsealed storage areas we recommend the use of diatomaceous dust.

Fumigating grain trucks

Insect control should only be carried out in a sealed structure where the required concentration and time of exposure can be achieved. It is illegal under the Western Australian Health Act to move any commodity during the exposure or ventilation period of fumigation. Deliveries to receival bins found to contain traces of phosphine will be rejected. It is difficult to achieve gas tightness in a truck bin.

Plan ahead

If you plan to sell grain off your property later in the season it is important to ensure you have controlled the insects. Department of Agriculture and Food regulations require you to control all insects in grain before it leaves the property. All grain merchants now have a policy of nil-tolerance of grain insects. Fumigation of grain in a sealed structure is the most economic option in the long term. Investment in one sealed silo will give you over 10 years of efficient insect control provided the silo is regularly tested and seals replaced.

Fumigation under gas-proof tarpaulins in an emergency is a cheap short-term option. The tarpaulins are vulnerable to damage and will not remain gas-proof for as long as a steel structure.

Care with phosphine

Even low concentrations of phosphine are lethal to humans. Read the label and follow the manufacturer’s instructions carefully. Open the phosphine container in the open air, not in a shed or silo. Stand upwind and hold the container away from your face when opening it or applying tablets.

It is recommended the applicator wears PVC gloves and a full face respirator fitted with a dust and gas cartridge when handling phosphine tablets. Have another person standing by when you are fumigating.

Do the job from the outside. Never enter the silo after phosphine has been applied. Clearly mark all areas under fumigation with ‘Danger – phosphine ‘ signs. Warn all people on the property, particularly children, of the dangers.

A full-faced respirator fitted with the appropriate filter cartridge must be worn when removing the sheeting from a grain pile or bag stack. After removing fumigated grain and before entering an empty silo, ventilate for seven to ten days, depending on wind conditions and the size of the silo. Use a tray to apply phosphine tablets or use sachets. This enables the retrieval of phosphine residue. This residue is toxic: dispose of it by burying or immersing in water.

Source: Department of Primary Industries and Regional Development, Government of Western Australia