Coccidiosis, caused by protozoan parasites of the genus Eimeria, is still one of the most widespread and difficult to manage poultry diseases, causing considerable economic losses especially in the broiler industry.

Intensification of commercial poultry production has relied on effective prophylactic control of coccidiosis. The sequential introduction of sulfa-drugs, synthetic anticoccidials and then ionophores changed this, facilitating rapid increases in the scale and intensity of poultry production. Current levels of poultry production would not be sustainable in the absence of effective anticoccidial control.

Synthetic compounds

Synthetic compounds were the first actives to be discovered that controlled coccidiosis. Different synthetic products have different working mechanisms, although their exact mode of action is not always clear. In general, these products enter the intestinal cells and interact with the parasite, even when in an intracellular phase (for example in the schizont phase). Synthetic products are very strong anti-coccidial products which result in a significant reduction of the coccidiosis infection pressure.

Ionophoreanticoccidials

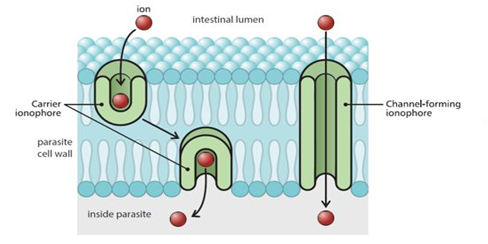

The introduction of ionophoreanticoccidials in the 1970s proved to be critical for the development of modern poultry production. Ionophores interact with ion transportation within the parasite, hence their name which is derived from the Greek ‘ion phoros’, meaning ‘ion carrier’. Ionophores transport ions (e.g. sodium (Na+), potassium (K+), hydrogen (H+) etc.) across hydrophobic membranes, in this case, the parasite wall (Figure 1). This increases the concentration of these ions inside the parasite, eventually resulting in the uptake of water through osmosis causing the parasite to swell and burst.

Figure 1.Illustration of ion transport by ionophores.Ionophores have two ways in which they transport ions into the parasite: by forming a channel or by acting as a carrier to pass the cell membranes. The carrier pathway (left) is used by ionophores applied in poultry

Slow resistance

One of the main characteristics of an ionophore product is the slow selection for resistance. Some parasites will always escape the effect of the product, known as ‘ionophore leakage’. This is an inherent property of all ionophores, linked to their mode of action. The consequence is that, besides the parasites with reduced sensitivity, some completely sensitive parasites will survive the effect of the ionophore. The competitive advantage for the resistant parasites is less pronounced and the shift to an increasingly resistant parasite population is a much slower process in comparison to synthetic compounds (Figure 2).

Figure 2.Resistant and sensitive parasite strain population following treatment with ionophore and synthetic coccidiosis control products. In contrast to synthetic products, ionophores will allow some parasite multiplication. This will result in higher shedding of sensitive parasites which will compete with the resistant parasites. As a result, the house will not be flooded by resistant strains.

Categorizing ionophores

The mode of action of ionophores makes them unsuitable for use as curative products. Ionophores will not enter the intestinal cells and are only able to destroy the parasite during the motile stages of the life cycle (sporozoites and merozoites). This means that, to be effective, the ionophoremust be present in the intestinal lumen at the time of the motile stages. It is therefore important to avoid interrupted medication since birds kept on litter ingest oocysts continuously.

It is very improtant to state that ionophores are antiparasitic products which also exert an antimicrobial activity. In parallel with their mode of action againstEimeriaas described above, the lipophilic ionophore attaches to the lipid-rich cell membranes of Gram-positive bacteria. Ionophores bind Na+. K+and H+and facilitate their transfer across the bacterial cell membrane, resulting in an increase in H+concentration inside the Gram-positive cell which eventually leads to the death of the bacteria. Different studies have demonstrated that the different ionophores all possess antibacterial properties which inhibit the growth of poultryClostridium perfringensstrainsin vitroand reduce lesions in a necrotic enteritis modelin vivo. The parasitic and antimicrobial modes of action however, are not related to any drug used for human medicine.

Ionophores and resistance

Till today, there is no proven evidence that the use of ionophores and cross-resistance or co-selection of resistance to antimicrobials critical in human medicine has been demonstrated. Since their discovery almost 50 years ago, ionophores have been the most popular products for coccidiosis control worldwide.

A coccidiosis toolbox without ionophores

When removing ionophores from the coccidiosis toolbox, awareness of the potential threats must be heightened. Coccidiosis is ubiquitous and it is generally accepted that, under current production systems, coccidiosis control remains necessary. When ionophores are withdrawn, there is an increased risk of sub-clinical and clinical coccidiosis because resistance issues caused by synthetic anticoccidial products will be more prevalent. The more products that are available for poultry producers means that an optimised rotation can be applied in a correct and responsible way. Coccidiosis vaccination might also prove beneficial here to manage resistance development.

Coccidiosis is one of the main triggers for other gastrointestinal disorders like necrotic enteritis and dysbacteriosis. Therefore, an increase in sub-clinical and clinical coccidiosis might also result in inreased occurrence of these intestinal disorders which, in turn, might increase the use of therapeutic antimicrobials via the drinking water. Animal welfare and sustainable poultry production will be compromised.

Conclusion

In summary, poultry production would not have evolved into the highly efficient meat production industry it is without the help of ionophores for the prevention of coccidiosis. Removing this crucial element of the coccidiosis control toolbox will unavoidably mean a reduction in poultry production performance, giving lower outputs and jeopardizing animal health and welfare. Due to the nature of poultry production and the features of coccidiosis, prevention of coccidiosis is crucial in order to remain competitive and ensure animal welfare and health. Prevention can only be achieved using all the available tools which includes chemical products, vaccines and ionophores in rotation programs. Using these tools at different time points will bring the most efficient and long-term viable strategy.